Recent Work

From Most recent, going back to 2014

[ stop the slideshow ]

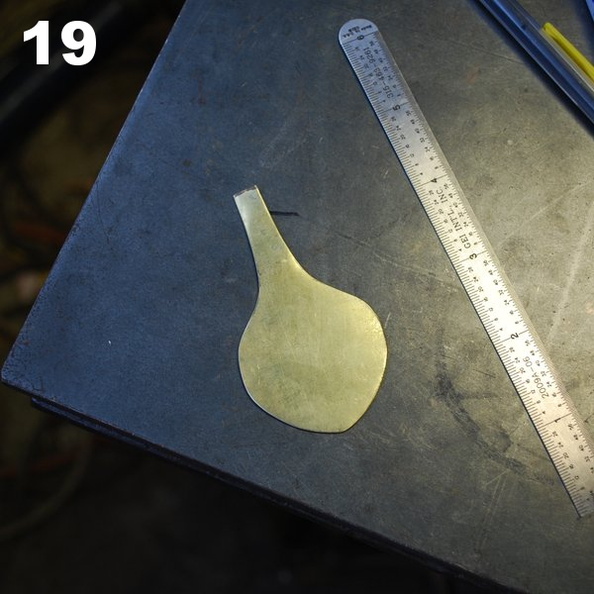

19. Starting the litte gnome or troll for the pull chain. Here's the blank cut out from 20 gauge brass sheet.

23/80

Powered by Piwigo

From Most recent, going back to 2014