107/792

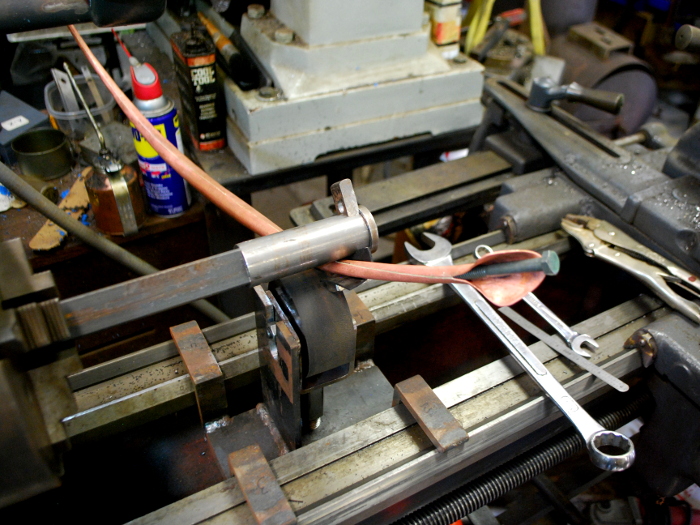

16. Here is the bending jig, evolved greatly over several weeks of experimenting, mounted in my lathe (unpowered). The mandrel around which the snake will be coiled is 1.25" diameter steel. The roller underneath, which can be moved up or down, and side to side, is made from 90A polyurethane.

- Author

- Steve Shelby

- Created on

- Monday 16 September 2019

- Posted on

- Friday 27 September 2019

- Keywords

- coiled snake, copper sculpture, hammered metal, metal art, metal sculpture, metalsmithing, shelbyvision, Steve Shelby

- Albums

- Visits

- 3430

- Make

- NIKON CORPORATION

- Model

- NIKON D60

- DateTimeOriginal

- 2019:09:16 18:37:15

- ApertureFNumber

- f/3.8

0 comments